A primary raw material in the glass container manufacturing process, silica sand is an important and longstanding part of the overall batch mix, used in the production of new food, beverage, cosmetics, pharmaceutical industries’ containers.

Melted, along with soda ash, limestone and recycled glass, the quality silica sand used daily in the country’s 47 glass container manufacturing plants is sourced and reclaimed routinely in a regulated and environmentally conscious manner. Glass is 100% recyclable and can be recycled endlessly without loss in quality or purity, giving glass producers the ability to reduce batch raw materials continually.

Sand Deposit Overview

There is more silica sand reserves available in North America than demand, and there are approximately 32 silica sand operations servicing the glass container industry, accounting for around 7.5 million tons per year of product used. The majority of silica sand deposits and operations are located near Class 1 and short line rail transfer points, reducing their travel related emissions as they head to glass container end market destinations, as part of a regionally sourced, closed loop manufacturing process.

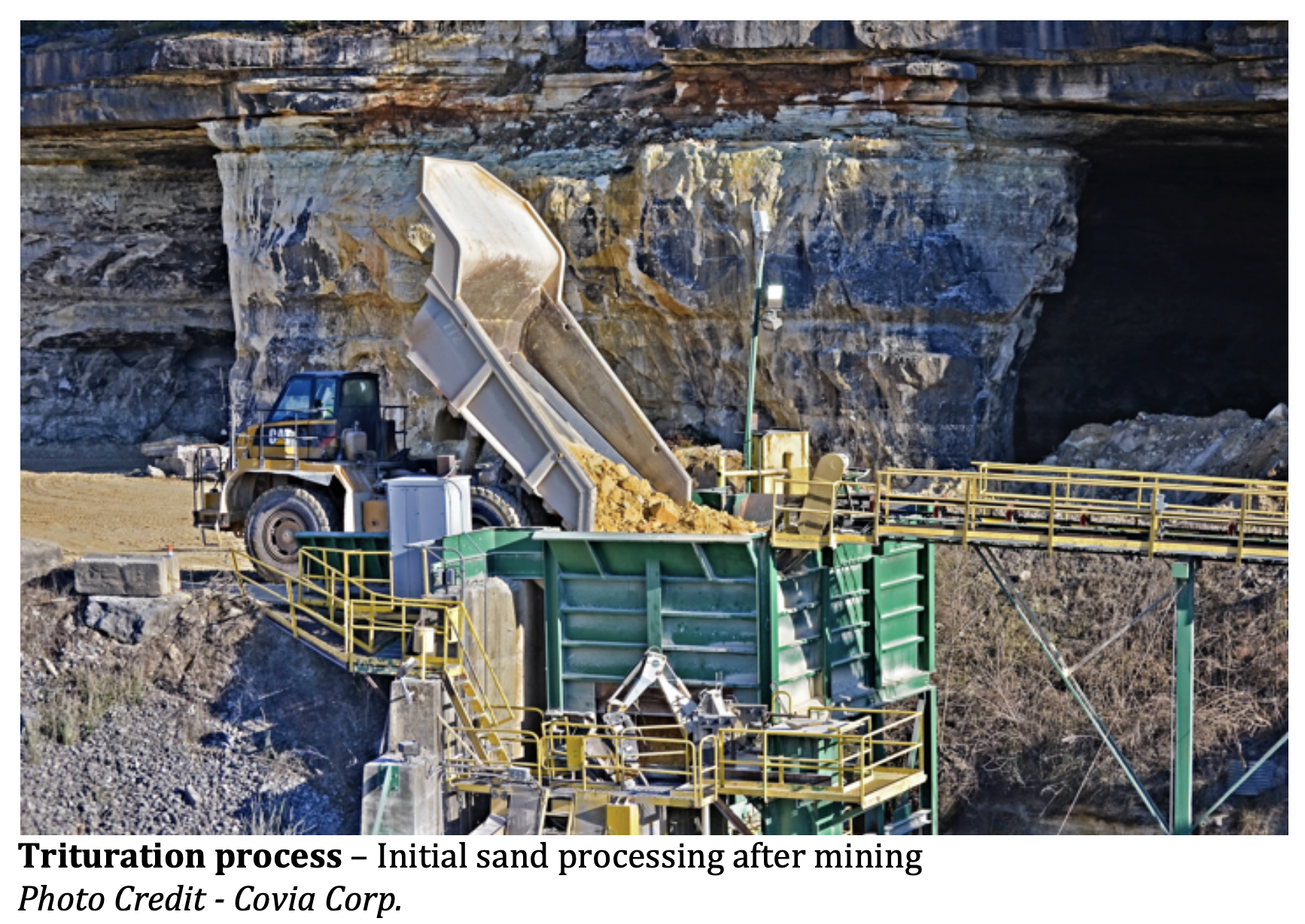

The silica sand sourced for North American glass container production comes from regulated, near-surface level extraction operation sites. Several companies oversee the majority of these operations, with ample domestic supply for container and other end market destinations with innovative and environmentally sound production.

Clarifying misconceptions regarding sand use and bottle availability

Not all sand is silica sand. Beach, riverbed and similarly situated sand deposits are not used in the glass container industry. Silica sand appropriate for re-melting in glass furnaces needs to meet detailed industry specifications and is not found in beach or riverbed areas, but in specific mineral deposits with proven multi-year reserves and properly reforested at the end of their useful life. Further, the North American silica sand industry does not compete, reclaim, or otherwise interfere with municipalities seeking to bolster their shoreline base, or similar efforts to prevent beach erosion.

There may be areas of the world where glass grade sand resources are limited. These issues are most often related to construction and concrete applications. While silica sand can be used in a multitude of applications for everything from filtration, construction and building materials, to backfill and other end markets; beach or riverbed sand is not alternatively used in glass container manufacturing. In impacted regions of the world, there has been recent discussion that global sand deposits and resources are inadequate. As explained above, these challenges are simply not present, nor the case, in the North American market. In fact, recycled container glass made with silica sand has increasing end-market applications in the construction and concrete industries, and in some instances has been used in beach restoration efforts.

Reports over the past year citing a lack of North American domestically available glass bottles and jars is a result of supply chain and tariff policies. The North American market collectively produces tens of billions of bottles and jars each year.

Customers seeking North American made glass containers also have the option to procure them directly from the manufacturing companies themselves.

However, countries where raw materials for glass may be limited, have experienced production slowdowns related to the COVID-19 pandemic, where increasing global vaccine-vial production, alongside tariffs and a slower delivery time for glass bottles being imported into the US and running into supply chain congestion issues, have led to the misunderstanding that a silica sand shortage is the primary cause of the unavailable bottles and jars. North American raw materials supply is strong and glass producers, who are deemed essential, are capable and continue to meet consumer demand.